Cooling Tower Repair & Refurbishment

PROAC Corp is a professional building maintenance company that helps businesses like yours with their cooling towers. A cooling tower is vital to the functionality of your company, process, and building. If it were to break as part of your HVAC system, you would need it repaired immediately.

Keeping an office building, school, hospital, or apartment building cool is vital. Keeping your production up and running is vital to profitability.

At PROAC, we are proactive with our maintenance so your cooling tower can last for many years. Your cooling tower or cooling towers are expensive pieces of your HVAC ecosystem. If neglected, you will see the expensive repair and replacement costs.

If maintained by PROAC, we will help your cooling tower last. Having a company prepared to repair your cooling tower will help you from being blindsided by a sudden leak from your cooling tower.

Schedule A Time To Speak With One Of Our Representatives

Need Your Business’s Cooling Tower Repaired?

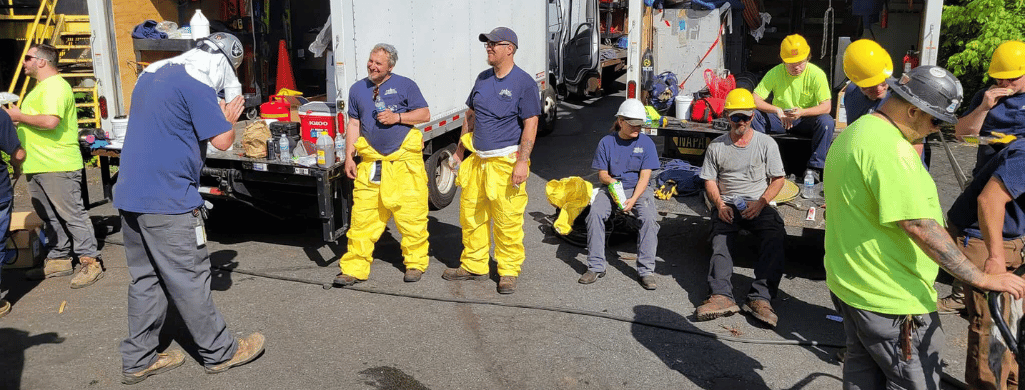

Having repaired, rebuilt, or refurbished a lot of cooling towers, we have seen it all. Some cooling towers simply need to be cleaned regularly with a few corroded parts replaced or resurfaced, while others that are older or have been damaged by the elements require a lot more attention to detail to fix. Below are a few of the common types of cooling tower services we provide:

Having repaired, rebuilt, or refurbished a lot of cooling towers, we have seen it all. Some cooling towers simply need to be cleaned regularly with a few corroded parts replaced or resurfaced, while others that are older or have been damaged by the elements require a lot more attention to detail to fix. Below are a few of the common types of cooling tower services we provide:

- Cooling tower water leak repair/replacement

- Cooling tower fan repair/replacement

- Cooling tower coil repair/replacement

- Cooling tower basin leak repair/replacement

- Cooling tower motor repair/replacement

- Cooling tower descaling

- Cooling tower decontamination

- Belt and oil changes

- Cooling tower fill replacement

- Crossflow cooling tower repair/refurbishment

- Counterflow cooling tower repair/refurbishment

- Regular cooling tower maintenance: Getting cooling tower maintenance and cleaning can help prevent or catch all of the issues listed above.

Is Your Cooling Tower Leaking?

PROAC can help you with your cooling tower repair. If you find your cooling tower to be leaking, we have the professional experience in getting your industrial cooling tower repaired or refurbished. We have seen a lot of corrosion, biofilm, and dirt build up leading to leaking. That is why we recommend checking and cleaning your cooling tower regularly.

Cooling Tower Maintenance For Your Business

If you own a large business with a cooling tower you know, it needs to be maintained regularly, especially if you are a hospital or school. Having a cooling tower break at your hospital would cause major issues and require a fast repair. An outbreak of Legionnaire’s Disease may be worse.

Save money and improve operating efficiency by refurbishing your cooling tower.

It is generally accepted that the lifespan of an industrial cooling tower is between 15 and 25 years. However, with proper cooling tower repair or maintenance, the initial life of the tower can be extended. Both the Cooling Tower Institute and the American Association of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) recommend placing cooling towers under an annual proactive maintenance program that includes:

- Pressure washing exterior and fill, cleaning and treating with a sanitizing agent.

- Repair/coat areas as needed.

- Lubricate fans and motor.

- Maintain biocidal treatment.

- Change belts and oil. Our experience includes changing fill in many types of towers.

- Additionally refurbishment includes cleaning the tower interior and sandblasting and grinding to remove rust.

Unfortunately, eventually structural components will begin to rust and fill will become brittle, negatively affecting the operation of the tower but is not always necessary to replace a failing tower with a new tower. Older towers can be refurbished at a fraction of the cost of replacement. We can also descale heavily scaled towers using a proprietary chemical treatment. Descaling results in increased heat exchange, resulting in lower operating costs. As with cooling towers, chillers loose efficiency over time. PROAC Corporation also has extensive experience refurbishing chillers. Our service includes blasting tube sheets to near white metal, applying a durable machinable silicon steel alloy with reactive polymers and oligomers to corroded tube sheets to restore a suitable profile to improve the efficiency of fluid handling equipment and to protect metals from erosion/corrosion. PROAC Corporation has been performing preventive maintenance on cooling towers since our inception in 1998. PROAC Corporation is a leader in cooling tower maintenance and repair. Our experience includes changing fill in many types of towers. Additionally, refurbishment includes cleaning the tower interior and sandblasting and grinding to remove rust. We use state of the art epoxy coatings on abraded metal parts and we utilize a flexible epoxy caulk to seal seams and prevent leakage. From our proactive cooling tower maintenance program to our complete tower refurbishment services, we can extend the life of your towers at a fraction of the cost of a new tower. Please contact us regarding our cooling tower maintenance and refurbishment services.

By scheduling regular maintenance and checkups for your cooling tower, you can prevent your commercial cooling tower from breaking and stay ahead of repairs. The cost of replacing an industrial cooling tower is astronomical; make sure you make yours last by getting your cooling tower serviced regularly.

Cleaning Your Cooling Tower

Preventative maintenance is a valuable aspect of the services we provide, and cleaning your cooling tower is part of the inspection process. In order to see your cooling tower motor, fan, fill, coil, or basin, we have to clean it. With regular maintenance, your cooling tower will be cleaned, and this will keep it from getting biofilm, dirt build up or damage.

Articles About Cooling Tower Repair

Contact PROAC For Your Cooling Tower Repair, Refurbishment & Maintenance

Looking for repairs? Maybe you want to contact us about getting your cooling tower maintenance regularly. No matter the urgency, contact us so we can take a look at your cooling tower and make sure it performs safely and efficiently for many years to come. Contact PROAC Corp. today!

Subscribe To Our Newsletter

Receive proactive building maintenance information.